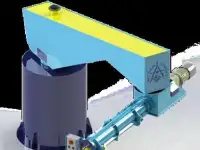

High-speed single-arm continuous mixer with a capacity of 3 to 10 tons of molding sand per hour. This mixer can be used both for the molding of half-molds and for the manufacture of cores by the cold-transferring process.

The company LLC "Litmashpribor" has the ability to produce for your enterprise a high-speed single-arm continuous mixer C110.

The mixer is designed for the preparation of cold-hardening mixtures for the production of molds and cores. Mixers of this design make it possible to significantly facilitate the manufacture of large forms due to the possibility of supplying the finished mixture to any point of the form. This equipment is analogous to the Omega company, the Spartan 210 model.

Application area:

The mixer can be used in foundries of individual, small-scale and serial production, using the Alpha-Set and Furan-process.

Benefits:

Reliability in operation

Easy to maintain

High performance

Aesthetic design

Large radius of action

Equipment productivity from 5 to 10 tons per hour

The equipment has the ability to change the performance and change the composition of the mixture.

Example:

program 1) 5.2 t / h - 100% fresh quartz sand, 1.6% resin (from sand) / 21% hardener

program 2) 6.1 t / h - 100% fresh quartz sand, 1.4% resin / 21% hardener

program 3) 9.4 t / h - 30% fresh quartz sand, 70% reclaimed, 1.6% resin / 21% hardener and 0.1% water

program 4) 7.8 t / h - 15% fresh quartz sand, 85% reclaimed, 1.6% resin / 21% hardener and 0.1% water

Product design:

The design of the mixer provides for the presence of one screw chamber made of wear-resistant steel with a thickness of 8 mm, and a high-speed rotating auger.

Авторизация