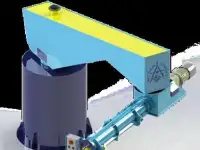

Hardness tester for raw molds, rods model 04412A is designed to measure the hardness surfaces of raw molds and rods, as well as to determine the fluidity of molding sands in accordance with GOST in molding and core sections, as well as in express laboratories, shop and factory laboratories.

Components of the device and principle of operation

This device consists of a body, which is designed to assemble all parts. The indenter and then the support surface of the sleeve are brought into contact with the surface of the mold or rod being examined. In this case, the indenter moves relative to the body by an amount determined by the surface hardness. With the help of the lever, the movement of the indenter is transferred to the indicator rod, as a result of which the arrow rotates. After removing the hardness tester from the surface under study, the spring returns the indenter to its initial position, while the hardness tester fixes the obtained hardness value. Moving the indenter by 5 mm corresponds to the rotation of the arrow by 360˚. The top of the hardness tester body is closed with a lid. The readings are reset by pressing the reset button on the indicator. Before starting the measurement, if it is necessary to align the arrow with the zero mark of the scale, turn the upper ring of the indicator.

Авторизация