This complex is designed for the preparation of cold-hardening mixtures in the production of molds and cores with the ability to work on the ALPHASET, PEP SET, CO2, COLD-BOX Resol + CO2, and FURAN process.

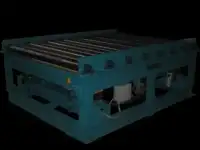

Complex with a productivity from 1 to 5 tons of molding sand per hour. It can be used for the preparation of cold-hardening mixtures in the production of molds and cores. The advantage of the FK5 molding complex is the absence of the need for commissioning.

The company "Litmashpribor" has the ability to produce for your enterprise a molding complex FK5 with a capacity of 1 to 5 tons of molding sand per hour.

It can be used in the production of molds and cores with the ability to work with ALPHASET, PEP SET, CO2, COLD-BOX Resol + CO2, as well as the FURAN process.

Benefits:

Compactness, no need for commissioning.

Equipment:

Mixer mod. S-105V.

Dispenser for one product with the ability to install three programs.

Storage bunker.

Support frame.

Fencing of stairs and bunker service platforms.

Control panel of the molder with functions: program selection, vibration table control, start / stop / pause mode switching.

Cabinet equipped with a Mitsubishi microcontroller and frequency converters, a touch screen, an air preparation unit, a resin and hardener filter, a pneumatic shut-off ball valve, a reed switch preventing the mixer from turning on when the auger is open.

Pneumatics of CAMOZZI firm.

Two metering pumps working with electromagnetic clutches (made of stainless steel and Teflon gears).

Including:

1 resin pump made by Fluid-o-tech Italy

1 pump for hardeners from Fluid-o-tech Italy

Авторизация