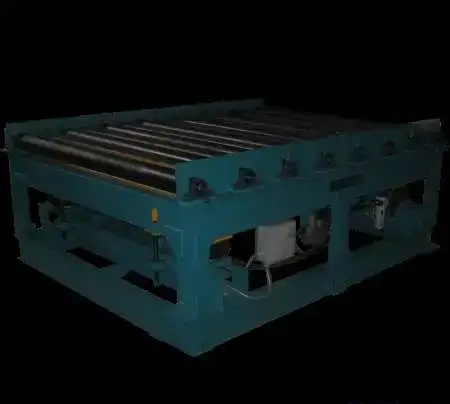

The vibrating table is designed to improve the fluidity of the molding mixture prepared by the cold-transferring technology.

The company "Litmashpribor" has the ability to produce for your enterprise both standard and custom-made vibrating tables designed for shrinking and compaction of molding sand prepared using the XTS technology.

Depending on the purpose, vibration tables can be equipped with driven and non-driven rollers, as well as frequency converters to change the frequency of vibration shocks.

When the vibrating table is supplied as part of a molding line or together with a mixer, its control is integrated into the mixer console.

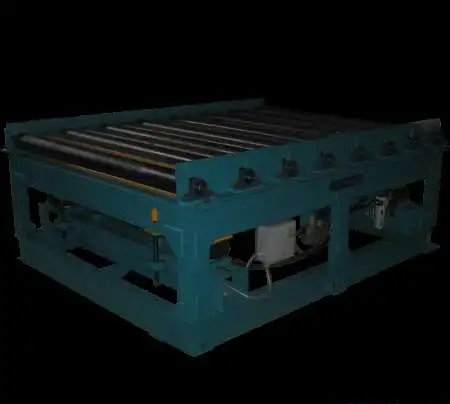

Benefits:

The main advantages of the vibrating table are:

Improving the quality of casting molds

High performance

Reliability in operation

Easy to maintain

Regulation of vibration frequency

Авторизация